D’Angelico New Guitars and Aged Mahogany Finish for 2021

New High End and Entry Level D’Angelico Acoustics

Retro Looks Awesome on Modern D’Angelico

Two new solid-wood models have been released by D’Angelico, each has mahogany back and sides, a Sitka spruce top with scalloped bracing and an abalone rosette, and a bound pau ferro fingerboard. They also feature the Scroll-style Excel headstock, seen for the first time on D’Angelico acoustics, and a Fishman INK-4 pickup system with controls in the treble side of the guitar, as well as an onboard tuner. Finish options include Vintage Sunburst, Walnut Stain, and Vintage Natural.

Click on Photo to Enlarge

Excel Tammany XT

Excel Gramercy XT

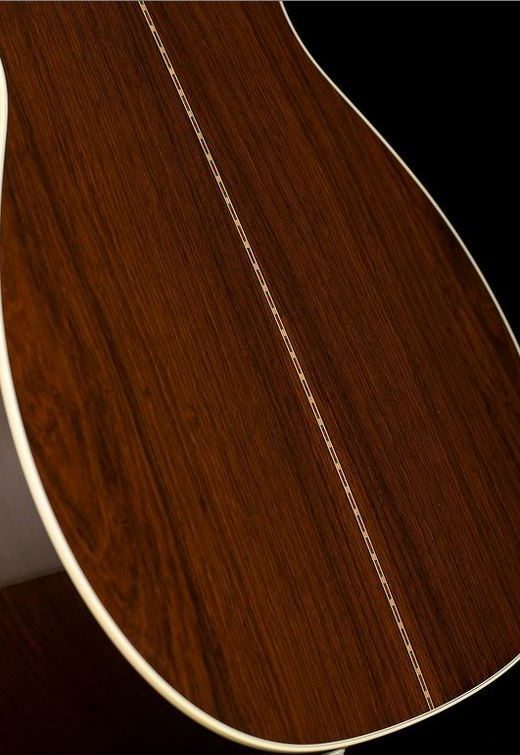

An upgraded, all-solid version of D’Angelico’s top-selling single-cutaway grand auditorium instrument, the Excel Gramercy XT is seen here in Walnut Stain.

Aged Mahogany Finish

D’Angelico’s Premiere Series offers affordable acoustic-electric models in various sizes and shapes made with laminated mahogany back, sides, and top, and an artistically distressed finish, equipped with an onboard preamp and tuner.

Visit D’Angelico Guitars to learn more